Doek turns simple sneakers into high craft. The Japanese brand makes classic tennis shoes in Kurume, in the south of the country, using traditional methods and materials. But while they’re slow to make, they’re sprightly in character: produced in vivid, classic colours, light to wear, and durable thanks to a vulcanized rubber sole. Perfect for the brighter, lighter days ahead.

Rubber-and-canvas shoes have been worn for centuries in military and sporting contexts, but the modern canvas sneaker came into its own in the early twentieth century with the introduction of Keds and the Converse All-Star. Doek’s Kurume factory had been making canvas shoes since the 1800s, but in the 1960s it was commissioned to produce the first canvas athletic shoe in the country by Kensuke Ishizu, founder of the legendary VAN fashion brand, and the man who brought Western prep to Japan.

Doek's Canvas Shoes

The Doek Court Canvas Sneaker in ecru.

Kurume city, in Fukuoka prefecture, might have been the perfect location to make sneakers, and Doek draws on a wide range of local expertise. The city is the home of Japanese rubber production (and birthplace of the world’s largest tyre manufacturer, Bridgestone). Doek still uses natural rubber. It’s vulcanised by expert hands rather than machine, to transform the soft, springy, high grip material into something far stronger and more rigid. Once the rubber is prepared, it’s moulded around the canvas shoe and baked like pottery in a kiln, irreversibly melting the sole to the upper.

The region surrounding Kurume is also famed for kasuri weaving, a traditional hand-loomed method that produces a richly textured and robust fabric. Using this technique, the canvas for Doek’s shoes takes three months to weave. As with many handmade fabrics, it’s imperfect and full of character.

The Doek Court Canvas Sneaker in indigo.

Finally, the area has a long history of expertise in traditional indigo dyeing. Following the original methods, the indigo plant is harvested, sun-dried, and fermented for several months. It’s this fermentation process that transforms the dye from a pale blue to the brilliantly deep, inky colour that’s then extracted by hand. When indigo-dyed thread is used to make kasuri canvas, it creates a beautifully rich yet varied surface, highlighting the unique character of each piece of cloth.

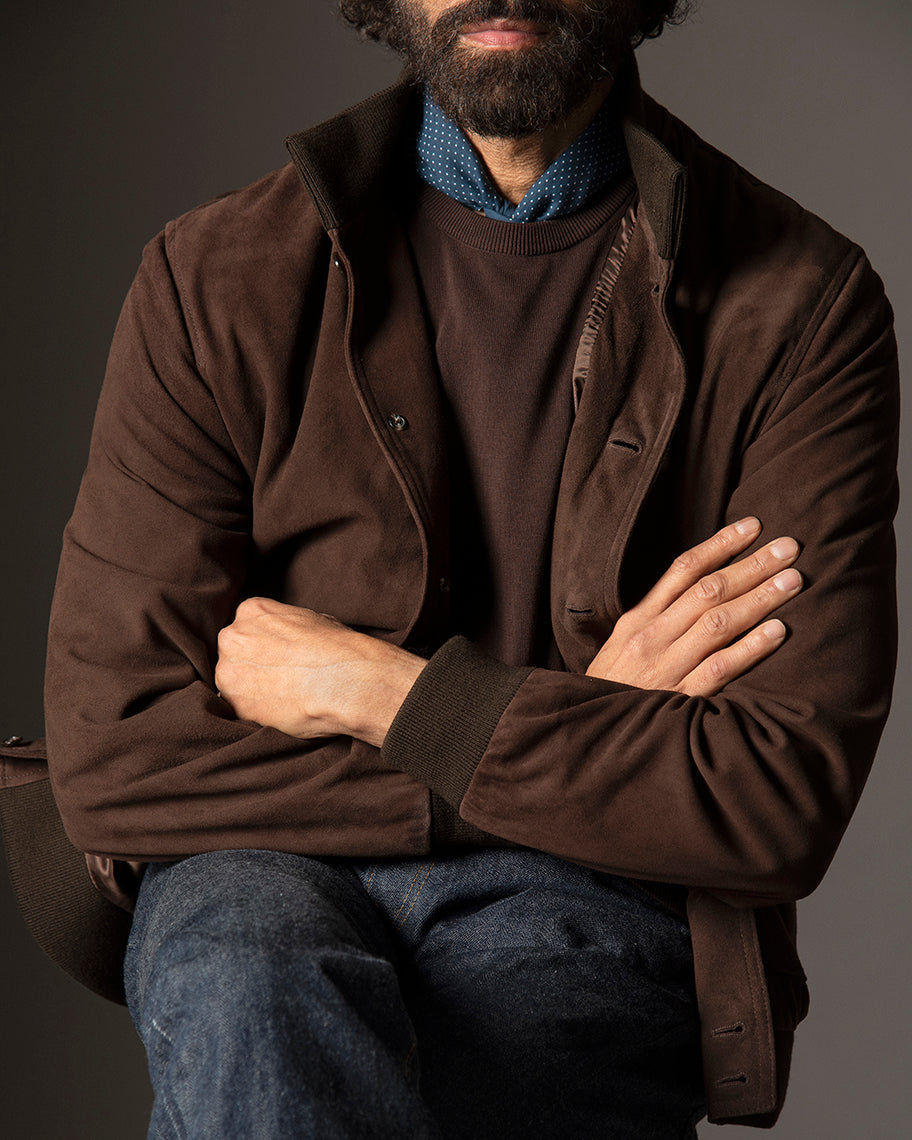

But for all the meticulous work and centuries of tradition, these sneakers wear their history lightly. Production might be complicated, but it’s not contrived; this is just the way things have always been done. They’re offered in two classic designs, a fuller, Oxford model and a slimmer, derby-style Court model with a rubber toe. They’re natural partners to other simple spring pieces with sporting and workwear roots: jeans and washed chinos, cotton sweatshirts and chore coats.

The natural materials, like the designs, age well. As with raw denim jeans, the shoe’s canvas will acquire its own shape and patina over time. The cork footbed resists moisture and slowly adapts to the feet that tread on it. And the natural dyes will evolve with the seasons. Like a great musician or chef mastering their tools and materials, sometimes the real gift of expertise is a capacity for unhurried simplicity.